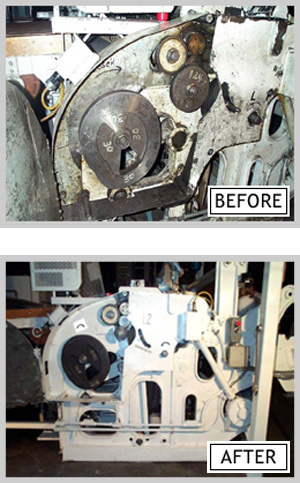

Detailed Cleaning and Painting

Well-maintained equipment equates to a reduction in operational issues for your business, quicker detection of equipment problems through equipment cleanliness, and ease of routine scheduled maintenance activities. In today’s business environment of economic instability, companies can no longer afford to needlessly replace old equipment with new due to a lack of equipment upkeep.

Well-maintained equipment equates to a reduction in operational issues for your business, quicker detection of equipment problems through equipment cleanliness, and ease of routine scheduled maintenance activities. In today’s business environment of economic instability, companies can no longer afford to needlessly replace old equipment with new due to a lack of equipment upkeep.

Plant Services can offer your business a cost effective solution to maintain and restore your valuable assets. We can maintain your equipment’s current luster or restore them to their original condition. Equipment wellness eliminates the necessity for replacement along with alleviating the need for purchasing and installing new equipment.

Industrial Equipment Services

Plant Services Inc. has developed expertise in several types of industrial cleaning services, based upon the type of machinery and its function. Upon evaluation, the team at Plant Services will determine which type of industrial cleaning is appropriate. These techniques include dry ice blasting, hydro blasting and cryogenic cleaning.

- Dry ice blasting has been successfully utilized for many different types of industrial cleaning: manufacturing equipment, welding equipment, tanks, printing presses, hulls, boiler tubes, process equipment and more.

- Hydro blasting is a safe and efficient technique used in cleaning machinery by removing built-up deposits on, in, or under machinery and equipment. Given that it is water-based and does not use any abrasive materials, hydro blasting does not cause dust pollution or leave spent abrasives for disposal.

- Cryogenic cleaning utilizes pressurized air and dry ice to dislodge surface contaminants. The principle involved in this maintenance process is to dislodge surface contaminants through the force of frozen carbon dioxide particles hitting the contaminants with high velocity, causing slight shrinkage of the contaminants, resulting in a disruption of adhesion bonds to the surface.

The key components in industrial equipment services include cleaning, lubrication, routine inspection and tightening. When you partner with Plant Services Inc. for industrial equipment services, we will work together to develop a plan that will make the planning and execution of these critical services an orderly, effective process to protect the vital assets of your business.